ppt on spring stiffness testing machine|stiffness testing machine : wholesaler Identify spring types (tension, compression, torsion) and appropriate applications (automotive latches, key fobs, pens). Disassemble and re-assemble padlocks. Measure stiffness and . Resultado da 11 de jun. de 2021 · Conhecida por vídeos de dança nas redes sociais, acumulando 1,5 milhão de seguidores apenas no Instagram, Danny Maria .

{plog:ftitle_list}

WEBHá quem evite jogar nas dezenas atrasadas da Lotofácil, e tem aqueles que jogam justamente por saírem pouco. Seja qual for a estratégia, as estatísticas nos mostram quais os números com menor incidência em sorteios. Da mesma forma, você também pode conferir os números mais sorteados da loteria, números que saíram diversas vezes em .

This document describes a spring stiffness testing machine. It begins by providing background on springs and their importance in vehicle suspensions. It then describes the design and operation of the spring .

This document describes an experiment to determine the stiffness of an open and closed coil spring and the modulus of rigidity of the spring material. A spring testing machine is used to apply loads to the springs and .DESIGN AND FABRICATION OF HYDRAULIC SPRING STIFFNESS TESTING MACHINE. Abstract- Springs isolate the driver from road imperfections by allowing the tyre to move over a bump without drastically disturbing the .

The machine is used for measuring spring stiffness for different spiral and helical springs in the range of 40mm to 60mm. Can be used in garages .

Identify spring types (tension, compression, torsion) and appropriate applications (automotive latches, key fobs, pens). Disassemble and re-assemble padlocks. Measure stiffness and .Spring stiffness is defined as the external force applied per unit deflection. Mechanical springs are one of the components which need to be tested before its final assembly. For any type of .Spring testing machine by FSA Canada conduct compression, shear, bending and hardness tests. It comes in two models, STM for helical coil springs and FST for leaf springs.

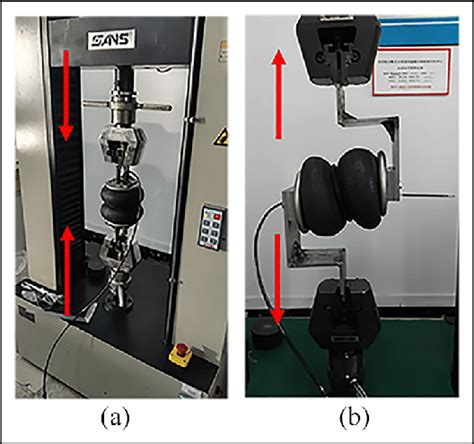

In the present work, manufacturing of single machine and its stiffness tester results are analysed for dual applications in measurement of walnut stiffness and spring stiffness .The document describes the design and fabrication of a hydraulic spring stiffness testing machine. The machine uses hydraulic principles to apply controlled force to compress springs .This paper illustrates the application of new method of testing spring through its frequency and natural frequency to calculate their stiffness and deflection values. Keywords: compression .

The spring for tension test is held on hooks between the upper and middle cross heads while that for a compression test is placed on collar between the middle and lower crossheads. Clutch mechanisms are provided to help to hold the .Stiffness (K) = TESTING RESULTS – SR. NO. LOAD (N) DEFLECTION (mm) SPRING STIFFNESS (N/mm) AVG. STIFFNESS 1. 60 60 1 2. 60 60 1 1 3. 60 59 1.016 Advantages - 1. Spring of different diameters can be checked without damaging it. 2. The testing process is carried out in very less time, so production rate is very high. 3.spring in the spring testing machine and load the spring by a suitable weight and note the corresponding axial deflection in tension or compression. Increase the load and take the corresponding axial deflection readings. Plot a curve between load and deflection. The gives the stiffness of the spring. OBESERVATION: Least count of micrometer = 0 .1. The document describes the design and fabrication of a hydraulic spring stiffness testing machine. The machine uses hydraulic principles to apply controlled force to compress springs and measure the resulting deflection. This allows calculation of spring stiffness. 2. The machine was designed with levers and cylinders to multiply applied forces and a load cell and .

SPRING TESTING MACHINE Hydraulic Spring stiffness testing machine mainly consist of following elements : 1. Hydraulic Jack 2. Microcontroller 3. Load Cell 4. Ultrasonic Sensor 5. Lcd display WORKING PRINCIPLE Working principle of this machine is based on the hooks law and Pascal‘s law, because for the application of load on the spring i.e. 1. Expt No: Date : SPRING TEST (OPEN & CLOSED COIL SPRING) AIM: To find the stiffness of spring and the modulus of rigidity of the materials of the specimen. APPARATUS: Spring testing machine, spring for tension or compression test, vernier caliper & balance. PRINCIPLE: A helical spring is formed when a wire of solid circular cross section is .

stiffness testing machine

Tensile testing ppt - Download as a PDF or view online for free. . A universal testing machine typically uses a hydraulic cylinder to apply the force. . elasticity, and stiffness. It provides diagrams illustrating how properties like tensile strength, modulus of elasticity, and breaking stress are calculated from the stress-strain graph .This preload value can vary depending on the stiffness of the spring. . and neglecting to set it properly could result in damage to the spring or the testing machine. Some precision machined springs can cost thousands of dollars per part and cannot afford to be damaged during testing. The key to creating a universal end-of-test criteria is to .For a spring the most important characteristic is stiffness under load. In spring testing machine we can find stiffness of spring having diameter ranges from 40mm to 70mm. The result obtained from this machine is verified with standard value. This machine is able to making testing of spring stiffness easier and affordable by automobile industries. A digital spring stiffness testing machine comprising hydraulic cylinders of different diameters interconnected by same liquid was designed by Jadhav et al. (2014).

how hard is the nasm test reddit

Machine Design Experiments using Mechanical Springs to . Measuring Spring Stiffness. Malak& Nagurka, Marquette University (ASEE 2014 . Test-Rig for Measuring Stiffness Malak& Nagurka, Marquette University (ASEE 2014) 3636 Stiffness of Parallel Springs. Malak& Nagurka, Marquette University (ASEE 2014) 3737 Spring Kit Malak& Nagurka . A universal testing machine is used to perform tensile, compressive, and shear strength tests on materials and structures. It consists of a loading unit, control panel, and control devices. The document outlines the components, working principle, and procedures for conducting compressive, tensile, and shear tests using a universal testing .

the amount of force required to produce a unit deflection is called the spring constant of the spring. In other words, F = kδ (1) Where F is the force in Newton, k is the spring constant or stiffness of the spring (N/mm) and δ is the spring deformation (elongation or compression in mm). Fig 1 Spring Loading apparatus

how hard is the nationa electrical code test

spring stiffness test machine

Testing Machine Manually handles test force and preliminary test force selection. Motor drive controls loading sequence. Twin type (Rockwell/ Rockwell Superficial) Hardness Testing Machine Twin type (Rockwell/ Rockwell Superficial combined use) Hardness Test equipment 2 HR-320MS (810-192-21A) HR-430MR (810-193-21A) HR-430MS (810-194-21A) Insert the spring in the spring testing machine and load the spring by a suitable weight and note the corresponding axial deflection in tension or compression. Increase the load and take the corresponding axial deflection . The developed fatigue strength testing machine had a designed machine capacity of 18875Nmm that sustained a motor power of 5.93kw.The machine shaft diameter determined to be 9.88mm developed an .

varying working load to the spring to realize the fatigue test of the spring. 4. Drive Train Design The scheme design of the mechanical drive system is an important part of the overall design of the fatigue testing machine. Its fundamental task is to convert and transmit the power generated by the motor to the actuating part

principle used in designing and developing of this spring testing machine. 2. Spring Stiffness Testing Machine “Spring testing machine are used for different purposes, this include SF1240 series spring testers which are commonly used to test stiffness of disc springs, ware springs, coil springs, and spring type components [1].” The traditional method for calculating static stiffness is based on statics and material mechanics, analyzing the structure of the machine tool and identifying several key influencing positions of the machine tool's static stiffness, such as movable joint guide rails, fixed joint bolts, bearings, etc. Li Liangfu studied the deformation of the contact parts which can be .Find here Spring Testing Machines, Spring Load Testing Machines manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Spring Testing Machines, Spring Load Testing Machines, Spring Compression Testing Machine across India.

This spring testing system is equipped with three test axes to measure the damping characteristics of the hydraulic shock absorbers.The vertical force (wheel load) is applied by the testing machine axis. Horizontal forces and torsional moments that occur when maneuvering curves, when starting or braking, etc., are generated by a horizontally mounted .

are called mass, spring, damper and excitation. The first three elements describe the physical system. Energy is stored by the system in the mass and the spring in the form of kinetic and potential energy, respectively. Energy enters the system through excitation and is dissipated through damping. The idealized elements of the physi-Typical lectromechanical Universal Testing Machine Test fixture for three point flex test. A universal testing machine (UTM), also known as a universal tester, [1] universal tensile machine, materials testing machine, materials test frame, is used to test the tensile strength (pulling) and compressive strength (pushing), flexural strength, bending, shear, hardness, and .

spring load test in different diameters and length of the spring. This machine can be used in various fields. This machine is simple in construction and working principle. Key Words: Spring, Ride height, Spring coil, Stiffness, Spring testing machine, Load, Deflection. 1. INTRODUCTION Spring rolling industry is a large and growing industry. Measurement of Load and Displacement. All testing systems have some sort of “loading train”, of which the sample forms a part.This “train” can be relatively complex - for example, it might involve a rotating worm drive (screw thread) somewhere, with the force transmitted to a cross-head and thence via a gripping system to the sample and then to a base . 3. G = modulus of rigidity x = deflection of spring q = Angle of twist When the spring is being subjected to an axial load to the wire of the spring gets be twisted like a shaft. If q is the total angle of twist along the wire and x is the deflection of spring under the action of load W along the axis of the coil, so that x = D / 2 q Again l = p D n [ consider ,one half turn of a .Stiffness and spring index are the main parameters of spring design. Spring stiffness is the force per unit deflection. These parameters are considered for defining the spring. In designing and developing the spring testing machine, this parameter is considered. Hydraulic principle considered while designing and developing the stiffness machine.

web1.2M 100% 6min - 720p. Kinky therapist helps Alyx Star overcome her phobia with her big cock in her wet pussy until he cums. 516.4k 98% 7min - 1080p. He likes bored and ignored fuck so he bought a toy. 166.9k 100% 6min - 1080p. Cuddle Fembot. 104.8k 100% 8min - 720p. Blonde babe with big tits loves that big meat thrusting deep in her tight wet .

ppt on spring stiffness testing machine|stiffness testing machine